|

Dave's Engine & Machine - Tech

Bore Motorcycle, ATV, Jetski and Snowmobile Cylinders

in Akron, Canton, Ohio area.

Dave's Tech Corner:

Two Stroke Cylinder Boring

How do we Bore a Motorcycle, ATV, Jetski or Snowmobile Cylinder?

Are you looking for someone in the Akron, Canton and Cleveland are who can Bore and Hone Motorcycle, ATV,

Jetski and Snowmobile Cylinders?

You have found the right place. Dave's Engine and Machine has been providing Cylinder Boring and Honing

Services since 1997! We specialize in Engine Machine Work for Motorcycle, Jetski, ATV and Snowmobiles.

Let's delve right into the Boring Procedure

First the Cylinders Gasket surfaces must be cleaned so that the cylinder can be mounted to the Boring Machine

squarely and level.

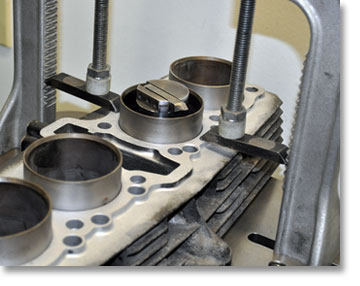

The Boring process begins by mounting the Cylinder on the Boring Machine also called a Boring Bar. A Boring Bar

allows the Machinist to precision resize a cylinder and at the same time keep it square to the deck or base of

the cylinder.

The Boring Bar's cutting tip spins and automatically feeds itself down into the bore cutting a perfectly round hole parallel to

the cylinder base. The Machinist will bore the cylinder within .002 to .003 thousandths of an inch of the desired final size.

This will leave room for Cylinder Honing.

The next step in the Cylinder Boring Process is deburring and chamfering of the cylinder. We will chamfer the

top of the bore just to break the edge. Next we chamfer the bottom of the bore to aid in the installation of the

piston and rings.

On Two Stroke Cylinders we will radius the ports in the cylinder with a right angle dentist sized die grinder.

Using a rigid hone with multiple stone grits the Machinist will then Hone the Cylinder almost to size with medium grit Honing Stones.

Then the Machinist will finalize the size and Bore Finish with a Fine Grit Honing Stone and a 35 to 45 degree crosshatch.

This will give the Cylinder Bore a surface finish that provides a good life span with proper lubrication and oil consumption characteristics.

After Picking up your Cylinder it should be thoroughly cleaned before it is reassembled. The fine stones that are used to finish

the bore will also imbed their abrasive into the cast iron walls of the cylinder.

You should wash your cylinder in hot soapy water rather than a solvent tank which won't get the abrasives out.

Dawn dishwashing liquid is known to work well for the final cleaning of a freshly bored and honed cylinder.

After cleaning and rinsing the cylinder, dry it quickly with an air blower. Next, using a clean white paper towel

with oil on it, thoroughly lubricate the bore. Look for traces of black or gray on the paper towel. If you see this

then you will need to reclean the cylinder.

When properly cleaned the white paper towel with the oil on it will look the same color on removal as it did when

you put it into the bore.

You are now ready to install your new piston into the cylinder and get back to riding!

See also Cylinder Honing

If you are in need of Automotive Engine Boring and Honing or other Automotive Services please contact our friends at

Greg's Engine & Machine in Copley, Ohio. Greg's Engine offers full Automotive

Machine work and Engine Rebuilding Services.

Let's Review the Cylinder Boring Procedure

- Bore the Cylinder to within.002 to .003 thousandths of an inch of desired final bore size.

- If 2 Stroke Cylinder then Radius or Smooth Port edges.

- Using medium grit honing stones, hone cylinder to less than .001 of desired final bore size.

- If 2 Stroke Cylinder then Ball Hone Cylinder in both Forward and Reverse to further smooth ports.

- Using Fine Grit Honing Stones, hone cylinder to final size with a crosshatch of 35 to 45 degrees using rigid hone.

|

|